Households that install small and medium-sized solar power systems (rooftops, factory roofs, offices, buildings, etc.) should regularly (quarterly) inspect their solar panels for large amounts of dust. There is very little dust on the panel surface due to the fact that high efficiency solar panels have a dust-proof coating on the surface and are installed at an angle to reduce dust.

However, since there is often a lot of dust in nearby areas such as thermal power plants, concrete and cement plants, it is important to pay attention to inspecting and cleaning solar panels. If you find a lot of fallen leaves, bird droppings, etc. on the panel, how to clean it. Sometimes manual cleaning can be a hassle, so having a solar panel cleaning robot can make it clean and quick.

Main content:

Solar panels require regular maintenance to operate effectively, and the effectiveness of the modules decreases over time as a layer of dust accumulates on their surface. Home solar panel systems typically range from 1 kW to 5 kW, like 3000w inverter and can be cleaned manually with wipers or brushes.

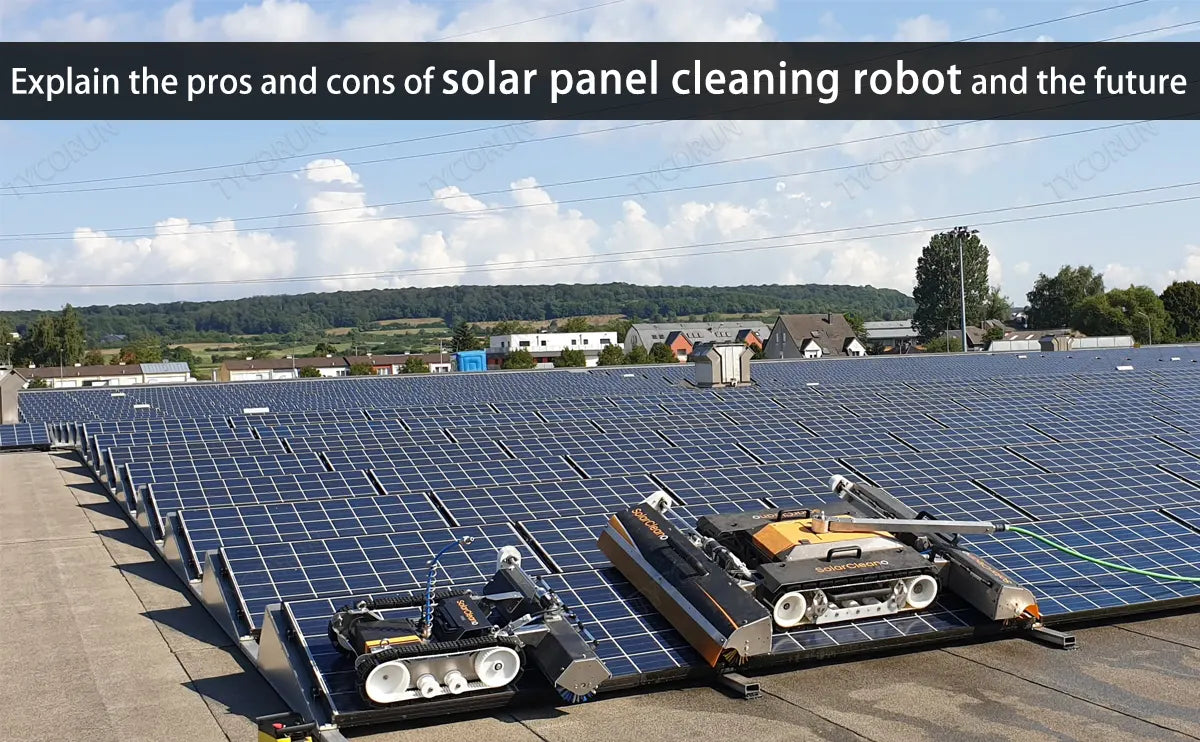

However, in large-scale centralized PV projects, it is challenging to clean each module manually. In this case, there are two cleaning options – hiring labor or using an automated system. Obviously, hiring labor is an expensive and time-consuming process. This is why the market share of solar panel cleaning robot is rising rapidly.

1. The advent of solar panel cleaning robot

Use a lot of water to clean the panels for solar projects. How to clean solar panel is a major problem for developers, especially in arid regions where water is limited.

As a result, the solar industry is struggling to move from traditional cleaning methods to more efficient and less water-intensive solutions. For example, dry or robotic cleaning.

Many solar panel cleaning robot technologies have entered the market, providing a more cost-effective alternative to manual cleaning of solar panels. Some of the more prevalent forms of robotic cleaning systems are modular cleaning robots, driving robots, and AI-enabled robots.

2. Problems solved by solar panel cleaning robot

The life cycle of photovoltaic power plants is generally as long as 25 years, and because they are installed outdoors, they have to go through changes in time and environmental pollution.

For photovoltaic power plants, dust pollution is an important factor affecting power generation. Not only will it reduce the amount of light irradiated by the module, affect the efficiency of the system, and reduce power generation, but local shading will also cause the hot spot effect, cause the loss of power generation, affect the life of the module, and cause safety hazards.

Therefore, in the operation and maintenance of power plants, the cleaning of photovoltaic module is particularly important. Currently, there are three common cleaning methods:

- Manual cleaning

- Equipment semi-automatic cleaning (manual+ sweeper)

- Robot automatic cleaning

3. Advantages of solar panel cleaning robot

With the growth of the PV industry and the rapid development of artificial intelligence, robotic cleaning could completely change the cleaning industry. The solar panel cleaning robot provides excellent system integration capabilities with real-time performance monitoring through a central management system.

Any faults can be notified by the system as soon as possible. Robotic systems for solar panel cleaning are also useful in arid areas. Manual cleaning is often accompanied by significant water wastage. The solar panel cleaning robot offers a breakthrough waterless method for removing dust from panels.

The manual cleaning method is the most commonly used method for cleaning solar panels. If the work is carried out by a professional firm, it will require a high fee. Over the past few years, many robotic technologies for cleaning solar modules have emerged that require little or no human power.

4. Solar panel cleaning robot future development

The use of robotic solutions for solar panel cleaning (with 12v 100ah lithium ion batteries in it ) is gaining traction and will become more cost-effective as projects scale. Very large, centralized developers and operators prefer automated cleaning solutions because the labor cost of cleaning panels increases rapidly as the project grows in size.

Due to lower labor costs in some regions, it may take some time for solar panel cleaning robot to completely replace manual cleaning, but as the cost of these solutions decreases, more and more investors will choose this innovative technology.

In addition, the dirt that accumulates on solar panels has a direct impact on the amount of electricity generated. Therefore, it is essential to clean the panels regularly so that they operate at maximum efficiency. Various cleaning solutions for different types of dirt are currently available on the market.

However, dry cleaning is the preferred alternative for large-scale PV projects. A large number of PV projects in arid areas require a lot of water to clean, but the local water shortage will lead investors to quickly switch to robotic waterless cleaning in the future.

5. Conclusion

In the coming years, with the rapid development of artificial intelligence, this technology is likely to pick up pace, and we will see more innovations related to solar panel cleaning robot that will become the standard for cleaning PV modules.

As one of the main tools of intelligent operation and maintenance, solar panel cleaning robot can not only solve a series of problems existing in traditional manual cleaning, improve power generation and income, but also have a good return on investment, which effectively promotes the de-manual operation and maintenance of power stations.

Related articles: distributed pv system, off grid solar batteries, top 5 PV module companies in India